![]() 400-678-6995 / 021-59946780

400-678-6995 / 021-59946780

| 序号 | 采购操作 |

|---|---|

| 1 | |

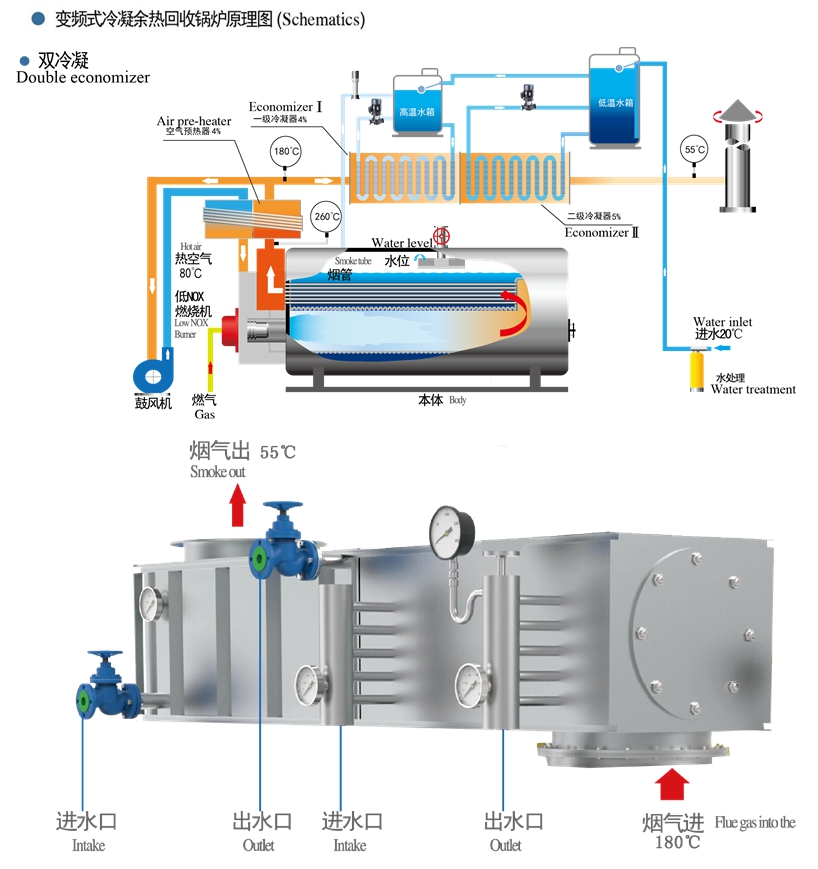

In general , the thermal efficiency of more than 100% of theboiler on the common sense is difficult to understand . but ifthe water vapor in the flue gas condensation latent heatutilized , and low exhaust temperatures drop low enough tosmoke damage is very low , the thermal efficiency of theboiler will be increased to 100 % ( calculated by the thermalefficiency of the boiler high calorific value of the fuel ) .

Of course , the fuel at low heat to calculate the thermaefficiency of the boiler , the thennal efficiency of 100 % o isimpossible to achieve . Efficient use of condensing heatexchangers and air preheater to absorb the rear of the boilerexhaust sensible heat and latent heat released bcondensation of water vapor , so sa to achieve the purpose ofimproving the thermal efficiency of the boiler . The use ofvariable frequency drive to achieve continuous watersupply , frequency nodulating burner , which is calledfrequecy condensing boiler heat recoery boilers.

1. Boiler body adopts a structure of two-retum and wet-back design.

2. Dual energy-saving devices are added to the end of boiler body

a.First, fin-tube bearing pressure steel economizer.

b.Second, atmospheric pressure steel condenser.

3. Equipped with high quality low Nox hot air bumer with a sufficientcombustion and low emission

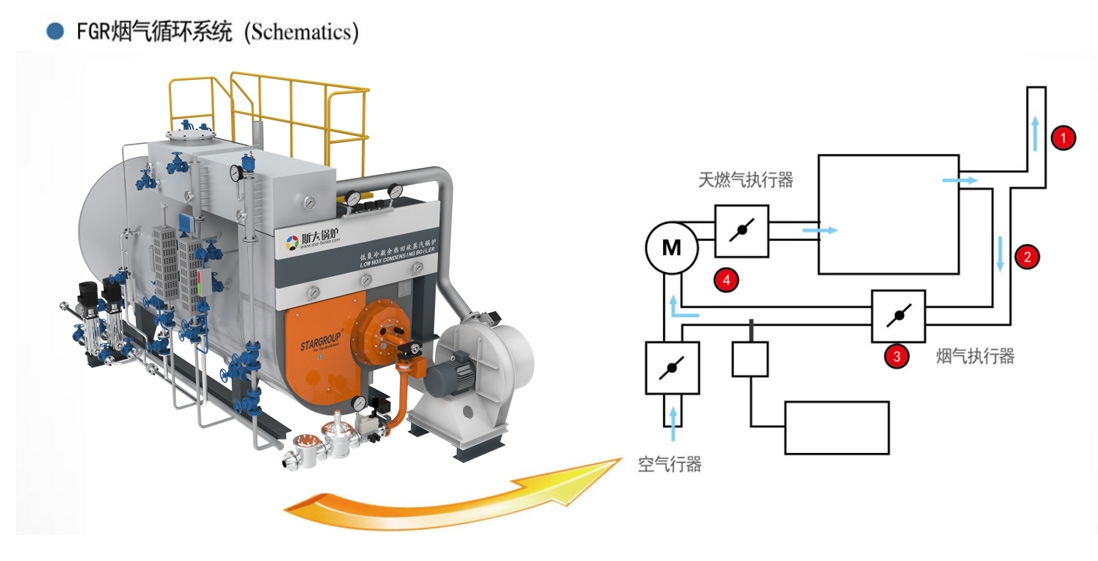

a.FGR system provides hot air

b.FGR back flash system, ensuring burner low Nox emissions

4. Boiler adopts the advanced color touch screen computer controller

5. Frequency conversion continuous water supply teclmology

6. Using frequency ratio adjustment combustion technology

7. Boiler has the functions of automatically adjusting steam pressureand water level, automatically ignites, and has the functions of waterack, overpressure and flameout protection

8. The boiler is entirely delivered, and has beautiful appearance and vivid color

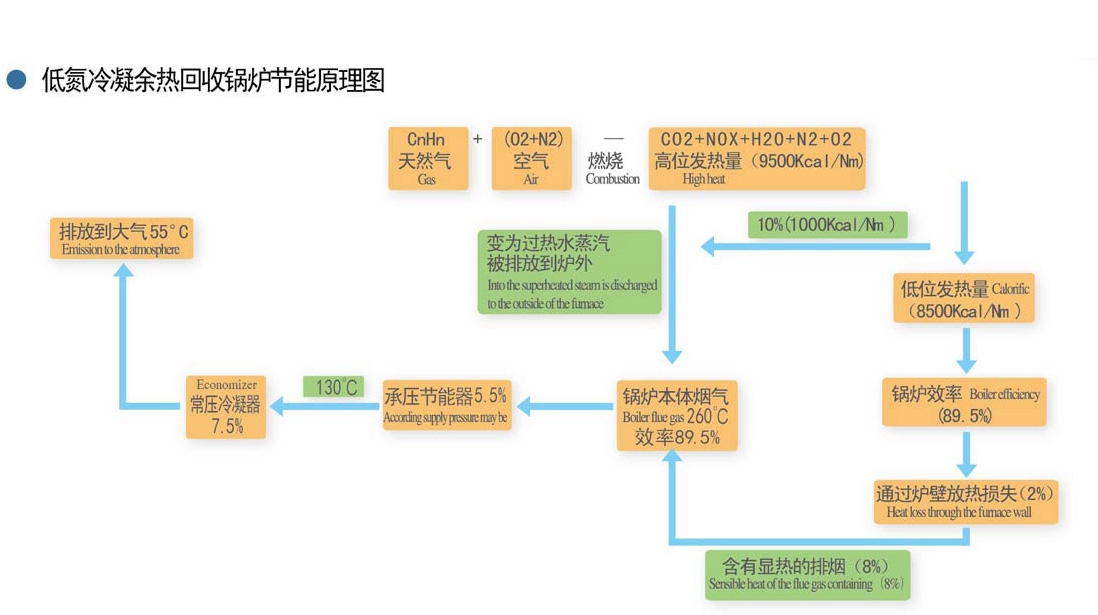

Theoretical effciency of the flue gas sensible heat and latent heat during recovery

Boiler efficiency when exhaust gas temperature 268 C: 89.5%

Boiler efficiency will be improved when first level condensation latent heat is recovered: 5.5%

Boiler efficiency will be improved when second level condensation latent heat is recovered:7.5%

Condensing boiler theoretical thermal efficiency: 102. 5%

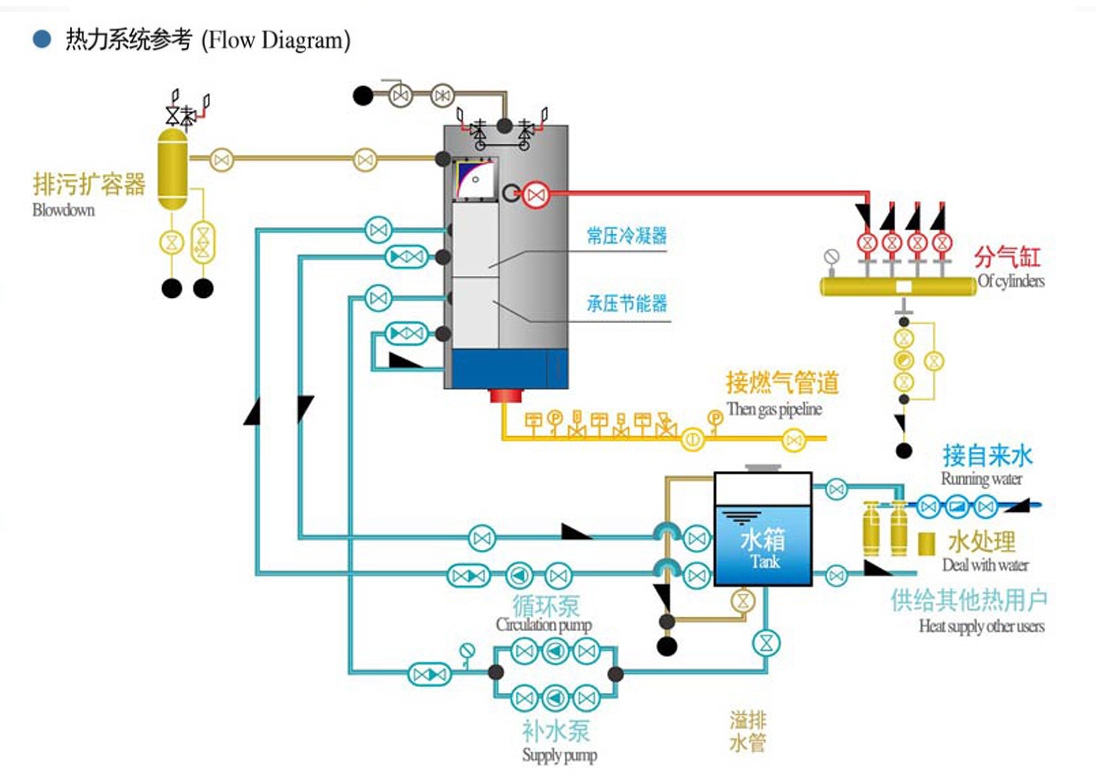

Water pump will make up water through fin-tube bearing pressuresteel economizer, effectively absorbing the sensible heat in the smoke.

The low Nox split hot-air burner preheats the air required for the fuel,realizing fuel sufficient buming and raising furnace temperature.

Atmospheric condenser and water tank cycle to fully recover the latent heat in the flue gas, controlling exhaust gas temperature within 60 C, to prevent the acid corrosion of condensed water. Fin-tube are manufactured by SUS304 stainless steel material. Compared with the straight tube, its heat conductivity is improved by more than 2 times than that of the straight tube.

Continuous frequency control water supply will realize 40% energy savings.

Using frequency ratio adjustment combustion techmology will realize 40% energy savings and reduce operating noise.

Through the FGR system, nitrogen oxides emissions of flue gas will be effectively controlled within 30mg.

Boiler feed water system will be equipped by manufactured, simple,beautiful and also save installation cost.

In sum, condensing heat recovery steam boiler is the crystal of the sciences like heat transfer theory, physics, combustion theory and materials science, etc. It is better than the traditional boilers with its absolute economical efficiency.

The popularization of the condensing boiler is an transformation on thought and conception. Meanwhile, it will inevitably promote the development on the field of heat engineering.

The thermal conductivity of heat pipe is 500-1000 times higher than that of copper-aluminum tubes.

The air preheater made of heat pipe is 2/3 smaller than the tranditional ones size and weight.

Installed in the front of boiler, occupying less space

Radial fin with excellently good thermal conductivity on the surface of tube can obtain larger heat-transfer area with small volume; with even temperature in evaporation part and condensing part,the expansion and contraction amount of heat pipe is small, which is a life-long device.

In order to prevent the acid corrosion of the condensation of the exhaust smoke and supply rustless clean hot water, this energy saver is manufactured by the stainless steel spiral extended surface tube.

Compared with the straight tube, the spiral extended surface tube the thermal conductivity of which is higher by more than 2 times is used,while the size and the weight are reduced by one second. The corrosion-resistant stainless steel material prolongs its service life.

The energy saver can be assembled on the upper part of the boiler to reduce the occupied space and the condensing water generatedon the heat-transfer surface can also be naturally discharged.

Boilers in use, out of the water valve must be normally open.

|

Save 40% of electricity consumption;

Save 40% of electricity consumption; |

Low excess air combustion technology

As far as possible in the combustion process under conditions close to the theoretical air amount , with the reduction of excess oxygenin the flue gas , the generation of NOX can be suppressed . This is one of the easiest ways to reduce NOX missions . Generally reduce NOX emissions by 15-20%. However ,if the oxyen concentation in the fumace is too low ( 3% ) will cause a sharp increase in the fuel concentration , resulting in incomplete combustion of fuel , causing an increase in the amount of carbon decreased combustion efficiency . Therefore , in boiler design and operation , should select the most reasonable excess air ratio .

Air staged combustion technology

The basic principle is that the fuel combustion pocess to be completed in stages . In the first stage , be reduced from the main bumer into the fumace for 70-75% of the total amount of air to the combustion air amount equivalent to 80% of the thoretical amount of air), so that the fuel in the first fuel-rich combustion conditions of hypoxia burning. When the first stage combustion zone excess air coefficinet a<1. thereby reducing the level of the burning rate and temperature in the combustion zone. Therefore, not only delayed combustion process and reduces the reaction rate of NOX generaed in a reducing atmosphere, the generation amount is suppressed in this NOX combustion. To complete the combustion of all remaining air required for complete ombuston through the burner is arranged above the main air jets dedicated OFA(over fire air)-called "fire upwind" spout into the fumace, with the first stage combustion zone mixing the flue gas in the " oxygen-lean burn conditions generated by the combustion process is completed in all a> 1 cindition. As the entire combustion process is divided into two for the required air into the fumace, it is called an air staged combustion method.