![]() 400-678-6995 / 021-59946780

400-678-6995 / 021-59946780

| 序号 | 采购操作 |

|---|---|

| 1 | |

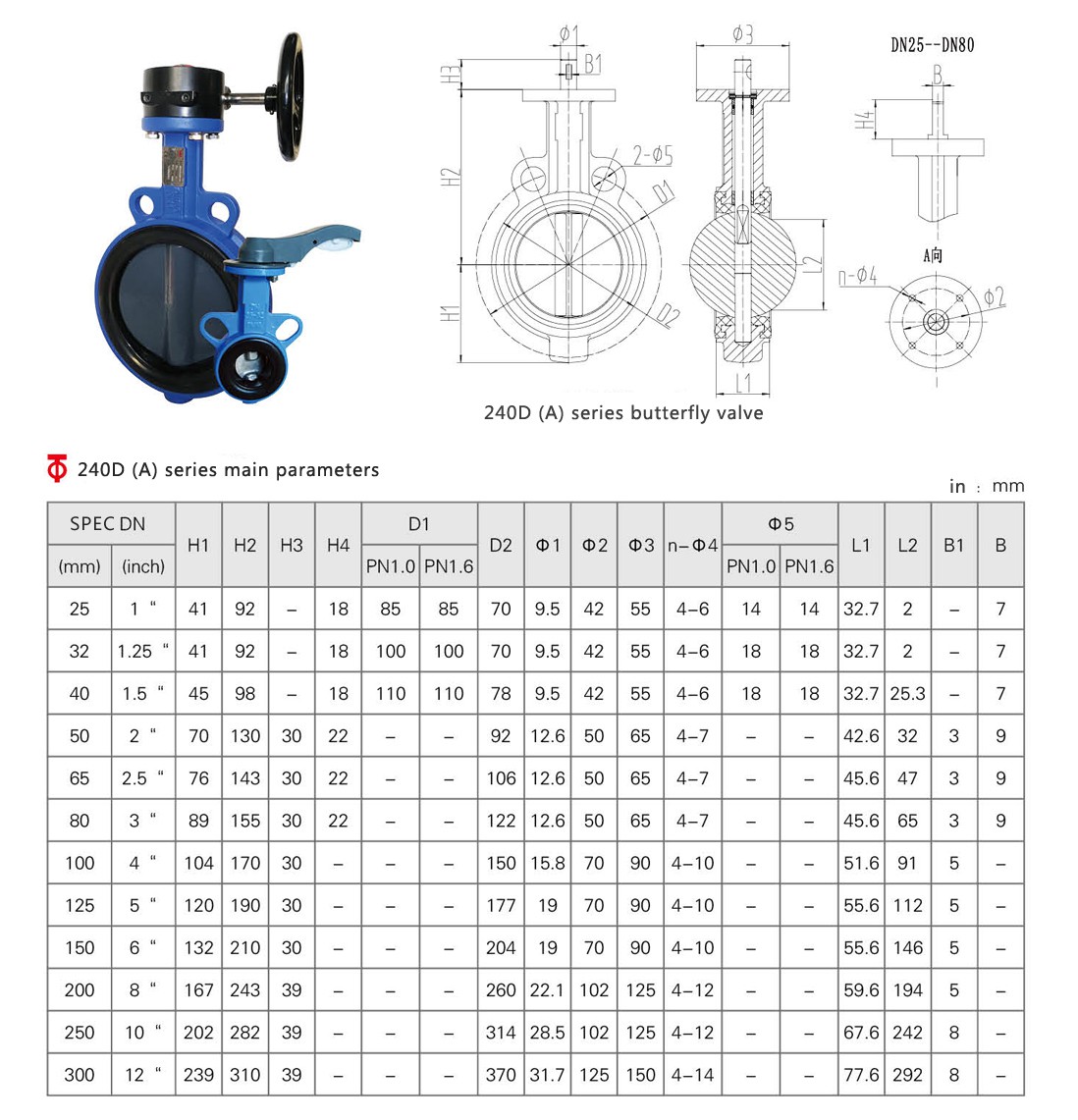

240 (A) aluminum body

Features

The valve body is made of light aluminum alloy, with a light weight as a whole, suitable for light pipelines, especially suitable for installation on non-metal pipelines.

The combination of nylon coating and epoxy polyester coating greatly enhances the corrosion resistance.

Skeleton-type two-way self-sealing ensures two-way sealing of the valve stem, which is suitable for vacuum working conditions and prevents external media from entering the internal cavity of the carcass.

The inner hole of the shaft is coated with nylon, which completely solves the problem that aluminum is not wear-resistant.

The tongue-and-groove valve seat can ensure the accurate connection between the valve body, the valve seat and the butterfly plate, and at the same time, the cymbal seat can be easily replaced.

Note : 1.DN50-DN300 side flange hole connection is in accordance with GB9113 (PN10 / PN16) / JIS 10K / ANSI CL150.

2. For butterfly valves ≥DN200, the sealing pressure shall be ≤PN10.

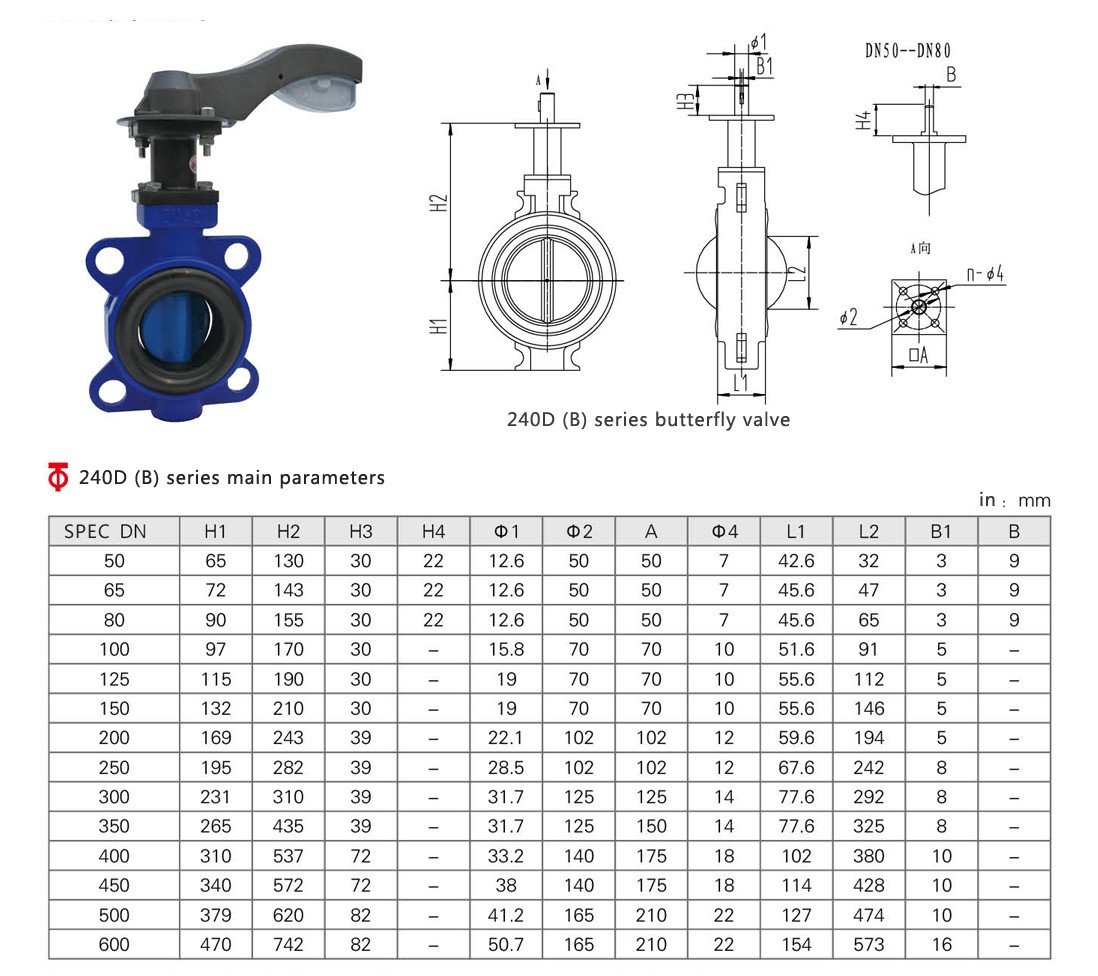

240D(B)anti-dew butterfly valve (new product)

Features

★ The valve body is made of ultra light aluminum alloy material, and its weight is only one third of the traditional butterfly valve. It is easy to use and install, and has strong anti rust performance;

★Light torque realizes the lightweight and miniaturization of the driving device, which reduces the cost of the whole machine;

★ The valve plate is processed according to a complete spherical surface, and each part of the sealing surface is a part of the spherical surface, even the upper and lower top end of the valve plate are axial sealing surfaces, which are not exceptional. Such sealing surfaces are relatively smooth even if there is contact, so the torque is reduced, and the sealing performance is improved, especially the friction at the axial sealing is reduced. The valve seat adopting this technology Three times longer life;

★ The long steel valve neck with aluminum valve body and vulcanized rubber blocks the conduction of liquid heat to the operating device of the valve without heat insulation treatment. Similarly, in the process of cold water transmission, condensation can be avoided;

★ Because the long valve neck adopts the technology of vulcanized rubber, it can effectively prevent the temperature difference of the valve body, isolate the transmission of medium in the pipeline, and achieve no condensation on the surface of the driver and flange;

★ It is suitable for heating, ventilation, central air conditioning water supply and drainage equipment, widely used in: water, gas, oil, chemical industry, refining, energy, shipbuilding, power, oil, water treatment, construction and other industries.

Note:

1: DN50-DN300 valve body is made of aluminum alloy, DN350-DN600 valve body is made of ductile iron.

2. The sealing pressure of DN200-DN300 aluminum butterfly valve is ≤ PN10; The sealing of nodular iron anti-dew butterfly valve can reach PN16 .