![]() 400-678-6995 / 021-59946780

400-678-6995 / 021-59946780

| 序号 | 采购操作 |

|---|---|

| 1 | |

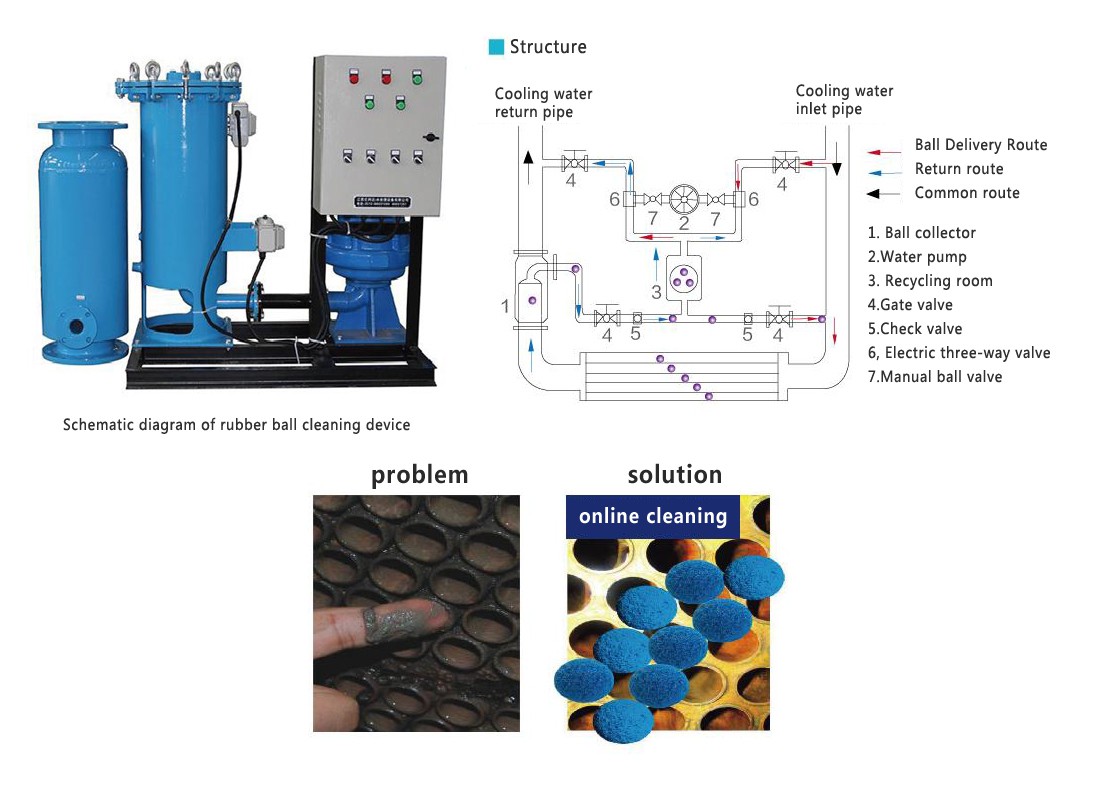

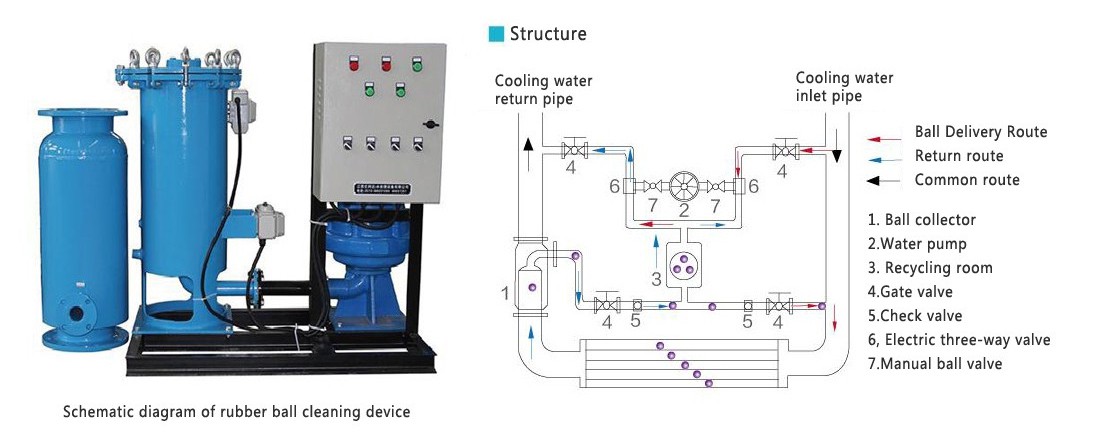

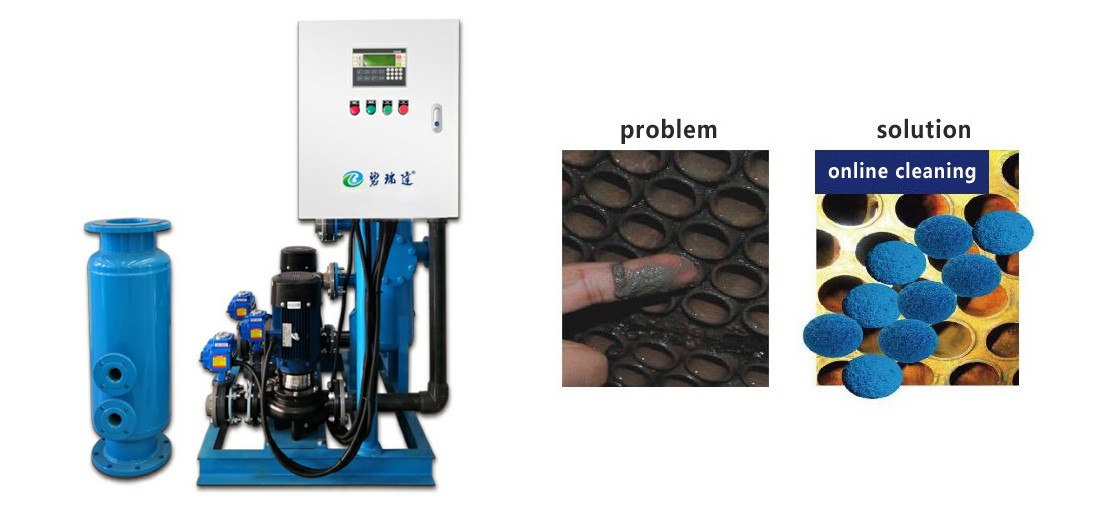

BRD冷凝器胶球清洗装置

■产品概述

冷凝器胶球清洗装置是一种在制冷机组运行时,使湿态直径略大于凝汽器换热管内径的弹性胶球在烻汽噐换热管内通过,通过对弹性橡胶球体的喷注和回收,实时周期清洗换热管道。在此过程中胶球擦洗换热管内壁,通过物理的办法自动在线清洗冷凝器换热管内壁,从而起到了清洗水管内壁沉积的污物和水垢,避免微生物的生长,防止腐蚀的作用,确保了换热管内壁清洁,保证了良好的换热效果,提高了机组的热效率。

■工作原理

选用合适的海绵胶球,且湿态比重和水相近。将胶球投入装球室,数量为凝汽器进水室铜管数的10%左石。然后启动胶球泵,打开系统两端球阀,胶球就在此循环水进口压力略高一些的水流带动下,进入凝汽器水室.因胶球是一个多微孔柔软的弹性体,在循环水进口压力差的作用下,被挤压通过冷却管,对冷却管内径进行一次抹擦,使管内壁污垢随水流带出,胶球随循环水经出水管进入收球网,在收球网板的阻拦下,把胶球分离出来,由胶球泵抽出重新回到装球室,如此循环往复对凝汽器冷却管实现连续自动清洗。

■产品特点

1)最低节能10%,最高可达40%。

2)自动在线清洗,保证冷凝器无任何积垢,腐蚀。

3)增加压缩机及管路使用寿命。

4)保证冷凝器处于最高换热效率状态。

5)PLC电脑程序全程控制,无需专人维护。

6)完全物理处理,节省化学处理成本,保护环境。

■技术参数

性能指标:收球率≥99%

输入电压:AC380V/50HZ

环境温度:温度≤55℃

压力损失:0.03MPa-0.05MPa

适用水温:0-+40℃

工作压力:≤1.6MPa

■ Product Overview

The rubber ball cleaning device of condenser is a kind of elastic rubber ball which makes the wet diameter slightly larger than the inner diameter of the heat exchange tube of condenser pass through the steam exchange tube when the refrigeration unit is running. The heat exchange tube is cleaned periodically in real time through the injection and recovery of the elastic rubber ball. In this process, the rubber ball is used to scrub the inner wall of the heat exchange tube, and the inner wall of the heat exchange tube of the condenser is automatically cleaned online through physical methods, so as to clean the dirt and scale deposited on the inner wall of the water tube, avoid the growth of microorganisms, prevent corrosion, ensure the cleanness of the inner wall of the heat exchange tube, ensure the good heat exchange effect, and improve the heat efficiency of the unit.

■ Working principle

The suitable sponge rubber ball is selected, and the wet specific gravity is similar to that of water. Put the rubber ball into the ball loading chamber, and the quantity is 10% of the number of copper pipes in the water inlet chamber of the condenser. Then start the rubber ball pump, open the ball valves at both ends of the system, and the rubber ball will enter the condenser water chamber driven by the water flow with slightly higher inlet pressure of the circulating water. Because the rubber ball is a multi porous soft elastomer, under the effect of the pressure difference at the inlet of the circulating water, it will be squeezed through the cooling pipe, and the inner diameter of the cooling pipe will be wiped once, so that the dirt on the inner wall of the pipe will be brought out with the water flow, and the rubber ball will go through the outlet pipe with the circulating water Enter the ball collecting net, separate the rubber ball under the block of the ball collecting net plate, pump out the rubber ball and return to the ball loading chamber, so as to realize continuous and automatic cleaning of the condenser cooling pipe.

■ Product features

1) The minimum energy saving is 10% and the maximum energy saving is 40%.

2) Automatic on-line cleaning to ensure that the condenser is free of any scale and corrosion.

3) Increase service life of compressor and pipeline.

4) Ensure that the condenser is in the state of maximum heat exchange efficiency.

5) PLC computer program is controlled in the whole process without special maintenance.

6) Complete physical treatment, save the cost of chemical treatment and protect the environment.

■ Technical parameters

Performance index: ball receiving rate ≥ 99%

Input voltage: AC380V / 50Hz

Ambient temperature: temperature ≤ 55 ℃

Pressure loss: 0.03mpa-0.05mpa

Applicable water temperature: 0 - + 40 ℃

Working pressure: ≤ 1.6Mpa