![]() 400-678-6995 / 021-59946780

400-678-6995 / 021-59946780

| 序号 | 采购操作 |

|---|---|

| 1 | |

|

机械过滤器 机械过滤器也称压力式过滤器,是水净化系统预处理的重要组成部分,其具有过滤阻力小、流量大等特点。主要用于给水处理除浊,反渗透以及离子交换软化除盐系统的前级预处理,也可用于电力、石油、电子、饮料、自来水、化工、治金、纺织、造纸、食品、游泳池、市政工程等各种工艺用水、生活用水、循环用水和废水的深度处理领域。根据过滤介质不同可分为石英砂过滤器、活性炭过滤器、除铁锰过滤器、多介质过滤器等。 石英砂过滤器 活性炭过滤器 除铁锰过滤器 多介质过滤器 |

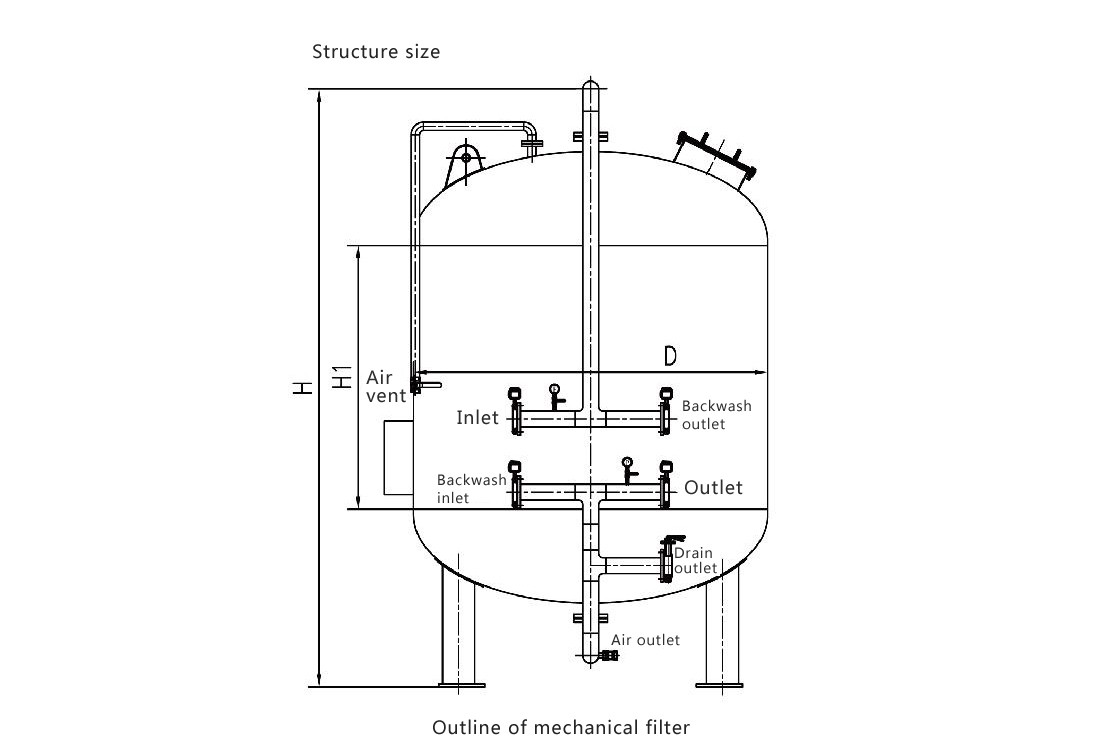

Mechanical filter Mechanical filter, also known as pressure filter, is an important part of water purification system pretreatment, which has the characteristics of small filtration resistance and large flow. It is mainly used in the pre-treatment of water supply treatment and turbidity removal, reverse osmosis and ion exchange softening and desalination system. It can also be used in the field of advanced treatment of various process water, living water, circulating water and wastewater, such as electric power, petroleum, electronics, beverage, tap water, chemical industry, gold treatment, textile, papermaking, food, swimming pool, municipal engineering, etc. According to different filter media, it can be divided into quartz sand filter, activated carbon filter, iron and manganese removal filter, multi-media filter, etc. Quartz sand filter Quartz sand is used as the filter medium, and quartz sand filter is generally used as the pretreatment of pure water equipment and ultrafiltration equipment. It mainly intercepts and adsorbs by filtering sediment, colloid, metal ions and organic matters. Because it has no pollution, low price and low operation cost, it is widely used. Activated carbon filter The base is composed of activated carbon particles. The activated carbon particles in the carbon bed have many micropores and huge specific surface area, and have strong physical adsorption capacity. In the water quality pretreatment system, the activated carbon filter can absorb the residual chlorine that cannot be removed in the previous stage filtration to prevent the later stage reverse osmosis membrane from being oxidized and degraded, and also absorb the small molecule organic matter and other pollutants leaked from the previous stage, which has a more obvious adsorption and removal effect on the peculiar smell, colloid and pigment, heavy metal ions, COD, etc. in the water. Iron and manganese removal filter Natural manganese sand is used as filter medium. The principle of iron removal is divalent iron ion in groundwater. After aeration, when it flows through the filter, it is adsorbed by the biofilm covered on the surface of the filter material, oxidized by dissolved oxygen under the catalysis, and adsorbed on the filter material. The ferric oxide generated by the oxidation participates in the new catalytic reaction as a new filter membrane, and the surplus oxide is washed away by backwashing in one cycle of the water to be produced. Due to the principle of ion selective absorption, iron is removed first and then manganese is removed. When the pH value is equal to 6.8-7.2, Fe (OH) 2 is colloidal coagulated and precipitated, which can be removed by filtration. Multi-media filter More than two kinds of media are used as the media filter of filter layer. Under a certain pressure, the water with higher turbidity is passed through a certain thickness of granular or non granular material, so as to effectively remove suspended impurities and clarify the water. The commonly used filter materials are quartz sand, anthracite manganese sand, etc. in the water treatment system, they are used for turbidity removal, oil removal, odor removal, softened water, pre-treatment of pure water, etc., especially for Effectively remove the tiny particles and bacteria that can not be removed by the sink ripple technology. |

|

产品特点: 1)设备造价低廉,运行成本费用低,管理简便。 |

Product features

|

|

技术参数

2)工作环境参数

3)运行参数

4)本体材质:不锈钢、碳钢衬胶或涂环氧树脂。 5)工作方式:手动、电动、气动 |

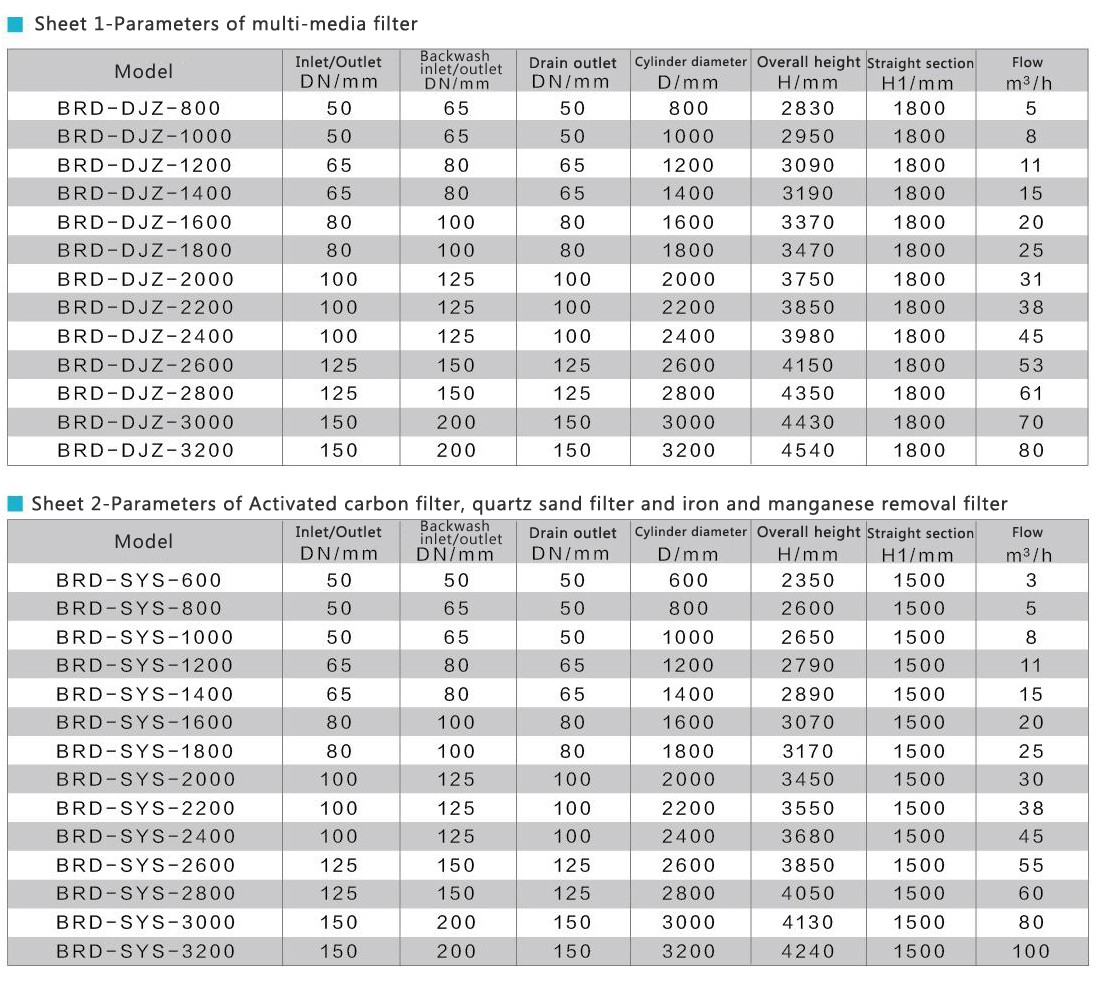

Technical parameters 1) processing effect

2) working environment parameters

3) operation parameters

4) body material: stainless steel, carbon steel liner or epoxy resin. 5) working mode: manual, electric and pneumatic |